INTRODUCTION :

Belt sander machine is a sander used in grinding and finishing wood and also other materials. Basically belt sander machine consists of an electric motor that turns a pair of cylindrical drums on which a continuous loop of sandpaper belt is mounted. But in this belt sander I have used drill machine instead of electric motor.

Belt sanders and disc sanders can have a very aggressive action on wood and are normally used to rapidly remove material from workpiece and the beginning stages of the sanding process. Sometimes belt sanders and disc sanders are also used for removing paints and finishes from wood. Fitted with sand paper of fine grit, a belt sander machine can be used to achieve a completely smooth and fine surface of the workpiece.

There are different types of belt sander available in the market such as handheld and moved over the material type and stationary (fixed) type, where the material is moved to the sanding belt or disc sander. Stationary belt sander machines are sometimes mounted on a work bench of workshop. Stationary belt sanders are also often combined with disc sander. Belt sander machine is also used for removing of non-ferrous metals, such as aluminium and other materials.

Sanding of wood produces a large amount of sawdust form the wood materials. Therefore, belt sanders employed in woodworking process are usually equipped with some type of dust collection system to remove sawdust. It may be as simple as a cloth filter bag attached to a portable sander or a large vacuum system to suck dust particles away into a central collector.

Parts Used :

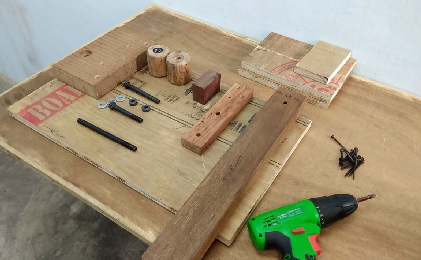

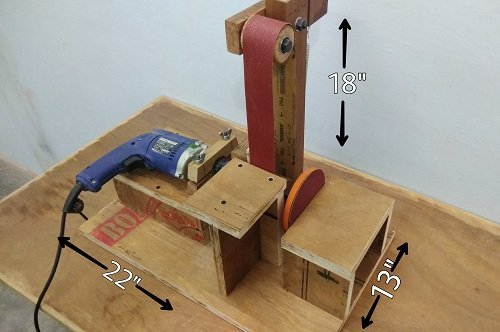

- Plywood sheet 22″*13″ ( 18mm Thickness)

- Support column (18” Height)

- Wooden blocks

- Round wooden blocks (Rollers) (2 pieces)

- Bolt threaded at the end with nut

- Bearings (4 piece)

- Spring

- Door bracket

- Drill machine

- Sanding belt (30” Length)

- Screws

- Bolt with nut (2 pieces)

- Iron plate for belt support

- Sanding disc 5”

How to make :

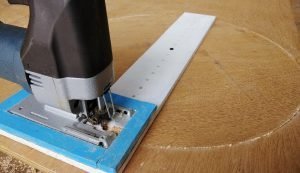

Step 1 :- Cutting of plywood sheet and wooden blocks

First step is cutting of plywood sheet to make a base of sander machine and also other parts of belt and disc sander machine. The base of plywood sheet is about 22” * 13” size.

After that, cut the support column of 18” length and support block and other wooden blocks parts.

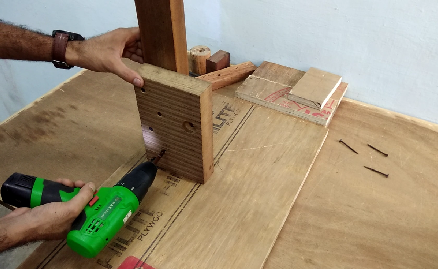

Step 2 :- Attach the support column and support block

Next step, attach the support column and support block with base plate of sander machine by using of screws. Also bearing is fitted in the support block for easy rotation of sanding belt.

Now attach the wooden block of 8” length on upper side of belt sander with support column and it is create angular moment about its centre of axis. This block is used to easy attachment and removal of sanding belt.

Spring is attached with upper block and support column for increase the tension in the belt. So the belt can be remains stable and tight in the proper position.

Step 3 :- Attachments of rollers and bearings

First of all bearings are fitted in the hole provided rollers and after that, attach these rollers, one with support block and other roller with upper block. These rollers are attached by using of bolts and nuts. Distance between the two rollers is 11”. Make sure that the rollers are rotate without any kind of vibration.

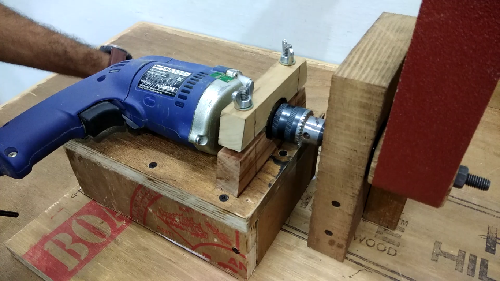

Step 4 :- Make a base support for drill machine

The base support of drill machine is made from plywood. For sanding disc, it is necessary to clamp the drill machine at some height for proper working of belt sander and disc sander machine.

Attach the all cut off plywood parts and make a support base for drill machine. Support base has 9” length, 7” width and 4” height. After that, attach this support base on base plate by using of screws.

Clamp the drill machine on this support base by using of clamping blocks, bolts and fly nuts. And also fit the main bolt of belt sander in the drill chuck by using of chuck key.

Step 5 :- Make a work support base

It is necessary to make a work support for proper working on the belt sander machine. Work support is made from plywood.

Attach the cut off plywood parts and make a work supports for both belt sander and disc sander. For disc sander work support, the door bracket (hinges) is attached with work support for easy removal of sanding disc. After that, attach this work supports on the base plate, one for the belt sander and other for disc sander.

Also attach the iron plate for belt support with support block using of screws for proper working on the belt sander machine.

Step 6 :- Attach the sanding belt and sanding disc

This is the final step of making of belt sander and disc sander machine.

Locate the sanding belt on the rollers in proper position and also attach the sanding disc at the end of threaded bolt.

The result is here. Now it is ready to use.

i like your belt and disc sander and i am interesting to built one myself can you please tell me the size of the rollers thats if you dont mind i be very thankful.

what is the measures of the bolts, and the thickness of the wood used? that’d be very helpful

Hello, i really want to make a belt and disk sander, can you send the dimensions, inbox me please

Very nice post. I just stumbled upon your blog and wished to say that I’ve really enjoyed browsing your blog posts. In any case I’ll be subscribing to your feed and I hope you write again very soon!|