INTRODUCTION :

A chop saw machine is a power tool that is used to make accurate cuts in wood, plastic, and metals. The chop saw has a fixed blade, attached to a moving arm that spins over a small workbench. Chop saws are used to create a rough, initial abrasive cut in a desired material like wood, metal etc. In principle, a chop saw is an electrically powered heavy motor which turns a high speed abrasive cutting wheel. Wide variety of parts can be machined by using this chop saw machine. The chop saw machine can make an straight, initial abrasive cut in a material to either make the piece of better workable size or to create rough outline of a desired shape of material. The chop saw machine is used in the initial stages of a project making because of the draft quality present in its work. Normally a initial straight cross cut is made with the chop saw machine table set at the 0° position.

An cut off machine or abrasive saw, also known as a cut off saw or metal chop saw machine, is a power tool which is typically used to cut hard materials, such as metals and wood. The cutting action is performed by an abrasive wheel, similar to a thin grinding process. The saw machine generally has a built in vice or other clamping tool arrangement, and has the cutting disc and motor mounted on a pivoting arm attached to a fixed base plate. They typically use composite friction cutting blades to abrasively cut through the steel. The abrasive wheels are consumable items as they wear throughout the cut.

Making of chop saw machine I have used 7” circular saw machine.

Parts Used :

- 7” Circular saw

- 12”*10” Base plate

- Circular saw support block 10” long

- Workpiece support block 7.5” long

- 4” Hinge

- Spring

- Screws and bolts

How to make :

Make a base

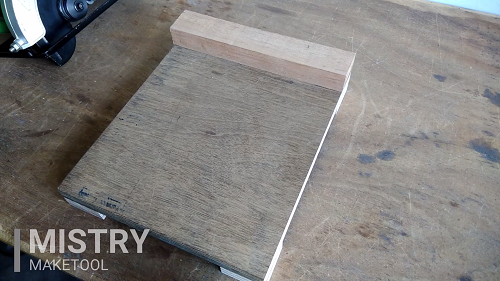

For base plate I have used 19mm plywood sheet of 12”*10” size. So first of all cut the plywood of 12”*10” size. Then after, attach the circular saw support block and also four blocks at four corner of base plate.

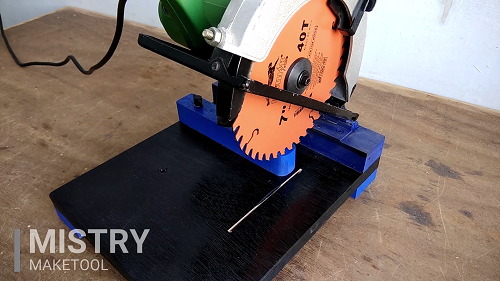

Attach the circular saw

Second step is attach the circular saw with base plate. I have used 7” circular saw in this chop saw machine. I have used 4” hinge to attach the circular saw with base plate.

Spring And workpiece support block

This is the last step of making of chop saw machine. Attach the spring with circular saw and base plate. Also attach the workpiece support block on the base plate for support of workpiece while cutting operation.

Attach the 7” blade in circular saw. You can use both TCT blade for wood and cutting blade for metal.

muchas gracias por este video, desde chile le envío un abrazo y felicitarlos ya que me sirvió mucho para potenciar el uso de mi maquina sin invertir mucho dinero 🙂

If I were to make one of these for a circular saw with a 165 mm blade, what height piece of wood would I want to use for the circular saw support block?

What a great idea, will try to make this, as one of my projects. Easier that buying one as I am new to woodworking. Thank you for the ideas.